Powering the Future of Data Center Operations

Powerman’s family of data center service robots is engineered to meet the evolving challenges of modern facilities. From high-density AI servers to sensitive UPS modules, Powerman delivers safety, speed, and system-level intelligence across the entire O&M lifecycle.

The Challenges Driving Innovation

Scale and Density

Hyperscale and AI facilities manage tens of thousands of servers. New GPU-based racks often exceed 100 kg per unit, creating handling risks and slowing deployment.

Efficiency Pressure

Every hour saved in installation or maintenance means higher availability and lower operational cost. Traditional methods cannot meet the pace of AI-era demand.

Safety and Compliance

Manual lifting exposes technicians to musculoskeletal injuries, while forklifts and warehouse carts are unsafe in narrow aisles. Data centers must comply with strict safety standards.

Digital Transformation

Operators expect integrated, data-driven workflows. O&M must align with asset management, DCIM, and scheduling systems — not remain isolated manual tasks.

Conclusion: The age of manual handling is over. Intelligent robotic solutions are no longer optional — they are mission-critical.

The Powerman Methodology

We approach O&M not as isolated jobs, but as digitally defined, robot-executed workflows that make operations predictable, scalable, and safe.

Ergonomics First

Intuitive controls, quick-swap pallets, and safe operation in tight rack aisles reduce fatigue and risk.

Automation-Ready

Integrates with openTCS, DCIM, and asset systems so digital job orders flow from IT to physical execution.

Scenario-Specific

Each model is optimized for its mission—compact handling, warehouse-to-rack transfer, or heavy-load lifting. Accessories extend capabilities.

Why Not Forklifts or Manual Tools?

Unsafe

Risk of tipping and collisions; carts need multiple technicians and lack braking precision.

Imprecise

IT gear needs millimeter-class alignment.

Incompatible

Narrow aisles, raised floors, hot/cold aisle layouts don’t fit warehouse equipment.

Disconnected

No integration with digital systems, leaving workflow gaps.

Our Product Family

DMS-A150M — Compact O&M Workmate

Entry point for robotic O&M. Lightweight and ergonomic with handheld U-unit controller and preset lift heights. Hot-swappable batteries keep shifts running — ideal for routine maintenance and UPS battery replacement.

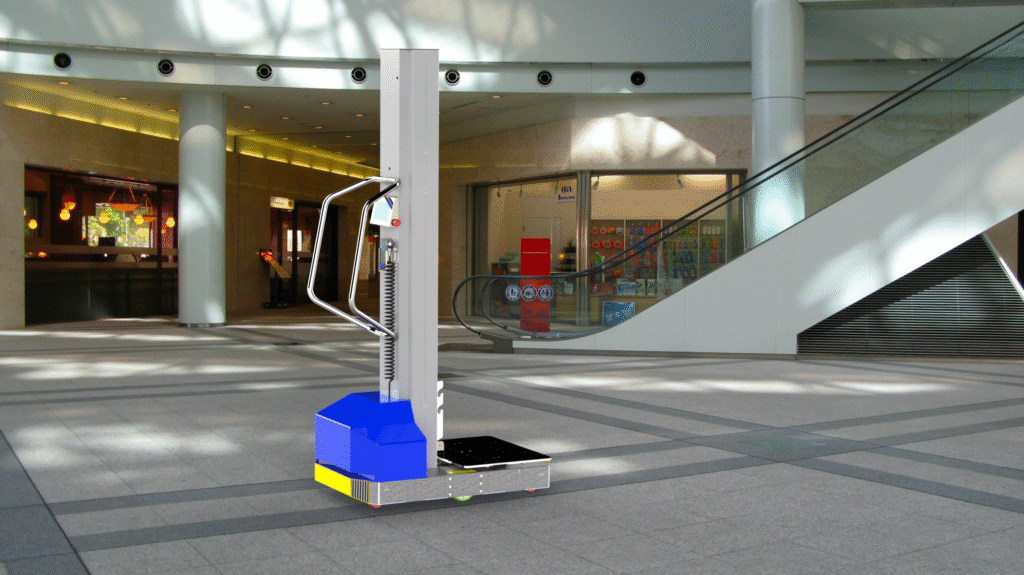

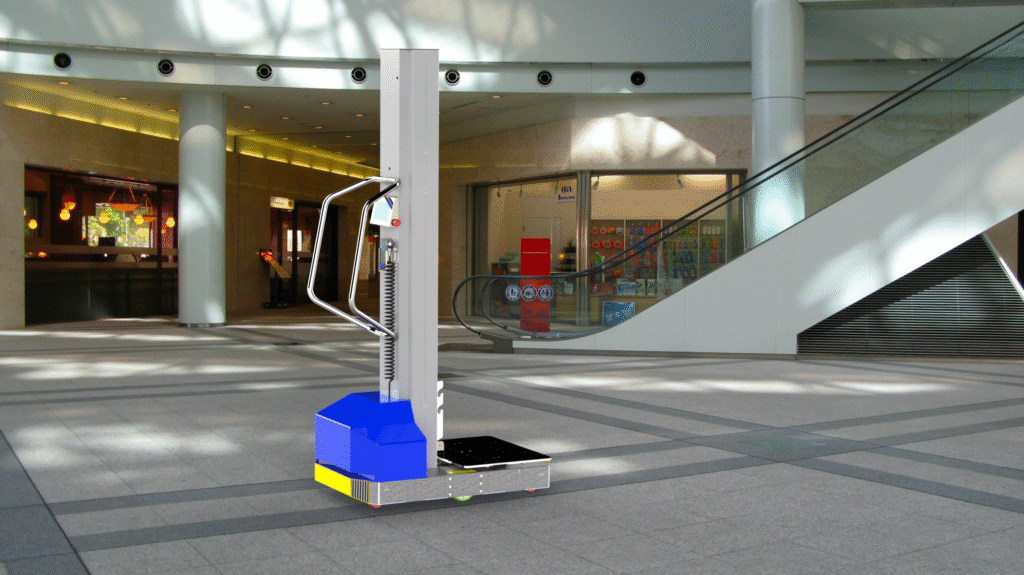

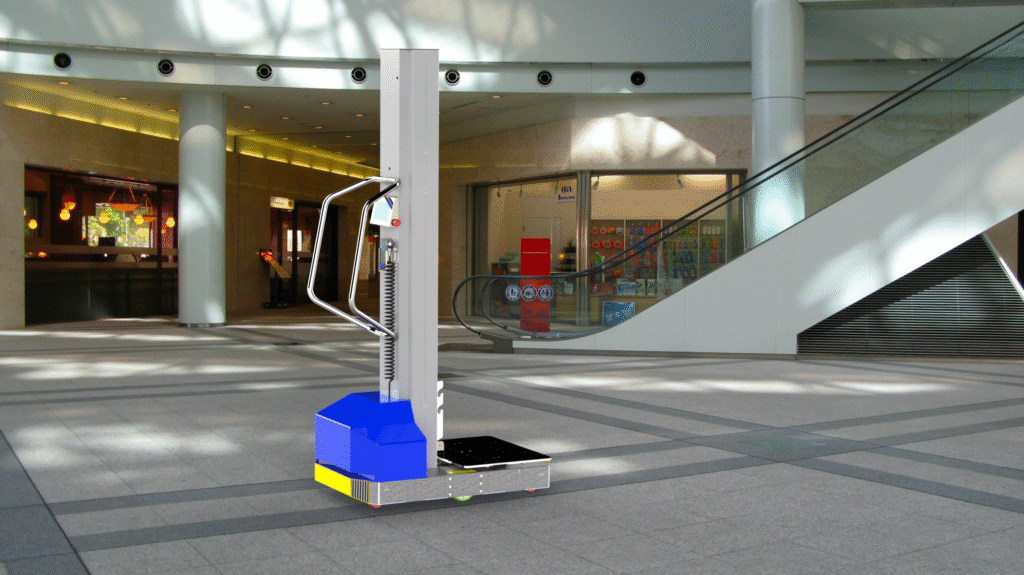

DMS-A250DDG — Warehouse-to-Rack Automation

Servo-driven ball-screw lifts and dual-drive chassis deliver precision and mobility. With openTCS integration, digital job orders define what to fetch, from which slot, and deliver to which rack U-position. Technicians supervise only at endpoints.

DMS-S500OMV — Heavy-Duty Omnidirectional Robot

Handles up to 500 kg with a two-stage cable+winch lift. Omnidirectional drive glides through confined aisles. Not hot-swap battery equipped, but enables safe handling of the heaviest equipment in Tier-1 facilities.

Accessories — Extending Capabilities

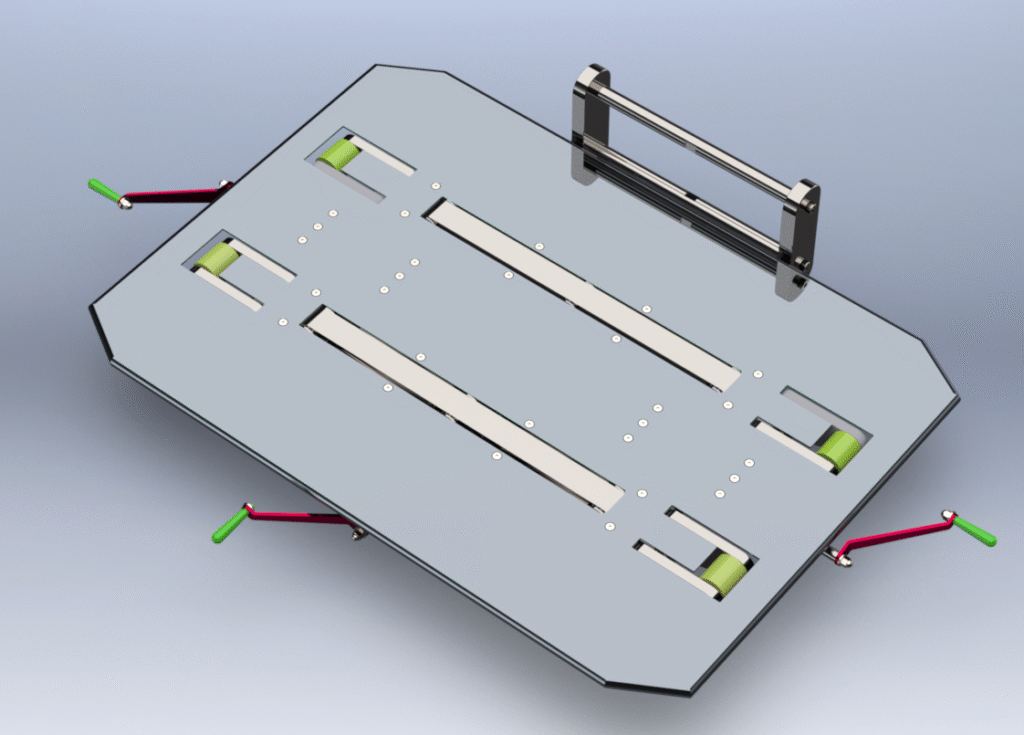

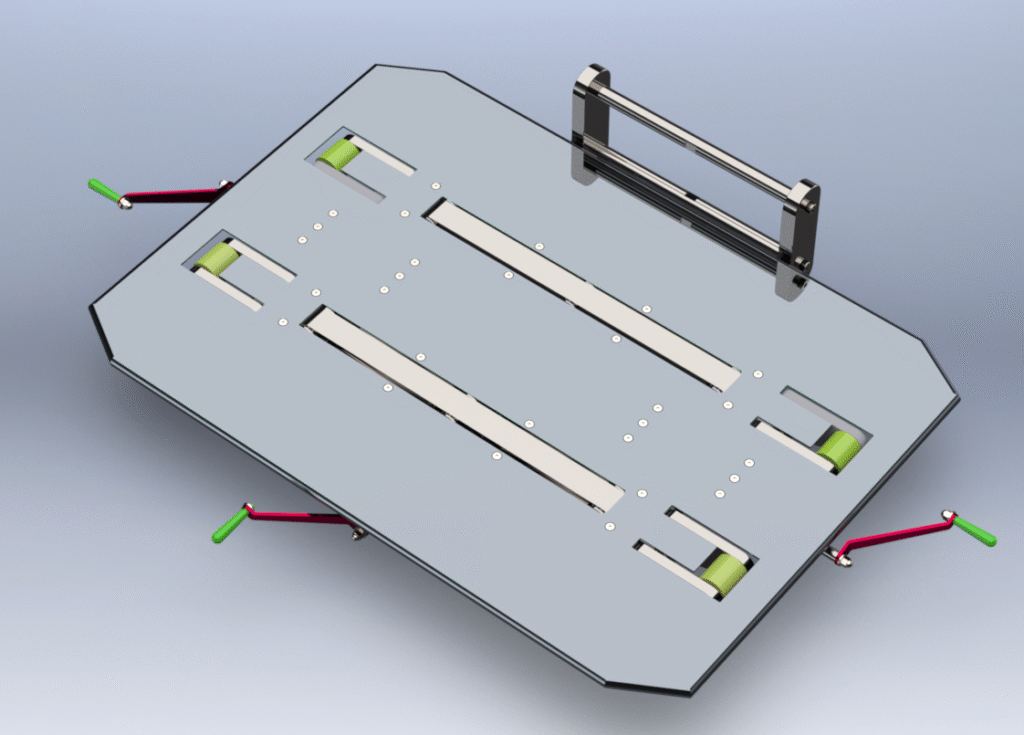

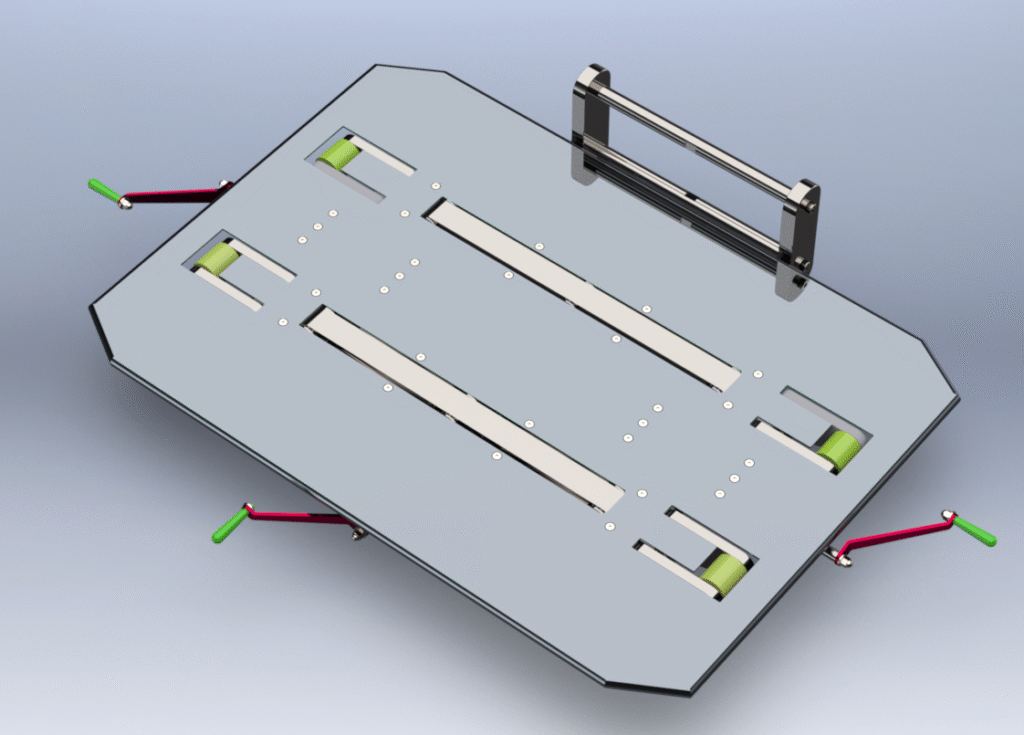

Server Pallet

Secure transport and precise rack alignment for servers.

Network Pallet

Designed for varied networking form factors.

UPS Pallet

Ergonomic, single-operator handling of heavy lead-acid modules.

Built for the Future

- Digitally defined workflows ensure repeatability and reduce errors.

- Scalable from Tier-1 hyperscale facilities to Tier-2 integration lines.

- Proven deployments in banking data centers and Nvidia-in-Rack assembly lines.

Powerman enables the next generation of safe, automated, and intelligent data centers.